MANUFACTURER OF ADVERTISING GADGETS | FAST DELIVERY TIME | FREE CONSULTING

Printing House

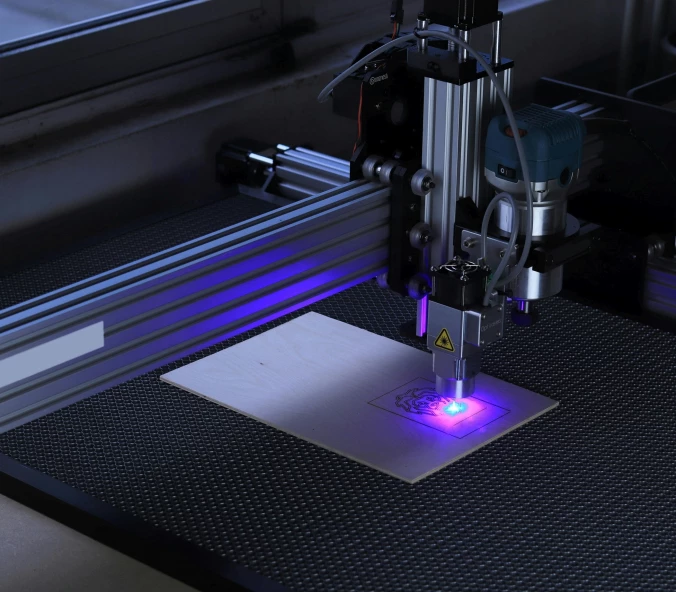

Laser engraving - what it is

It is a technique that enables very precise and permanent marking of various objects. This type of decoration can be carried out on all kinds of metals, coated metals, aluminium and precious metals. It is also possible to mark certain types of plastic. Laser engraving can be used for both artistic and purely technical applications. Using machines designed for this purpose, it is possible to produce any design or motif to decorate and personalise objects such as pens, metal key rings, mugs, pendrives or, for example, metal parts used in industry in various sectors such as the automotive industry. With this technology, personalised signatures can be created on awards or cups. In addition, due to the use of computer techniques, it is possible to create precise and repeatable designs, even on many hundreds or thousands of items.

See: promotional pens

For the curious and those who like durable and, so to speak, premium marking, we propose computer embroidery, about which we have also written a few words in another article.

Laser principle

The basis is to create a design for the pattern to be engraved on the item. This can be done in any graphics programme (preferably a vector graphics programme). Such a design is then sent to special software controlling the laser marking machine and, using it, is transferred to the selected surface.

See: printed lanyards

How does the laser work? Under the influence of electricity, photons begin to emit energy in the form of light, which is concentrated in the form of a beam, called a laser beam. The name 'laser' itself is an acronym from the English words meaning the amplification of light through the forced emission of radiation and best reflects the principle of the laser.

What effect does the laser have on the engraved surface? Under the influence of the laser beam, the material is strongly heated and its colour changes in contrast to its surroundings, which have not been exposed to the rays. Another process that can take place is the burning and fugacity of the material. This makes laser engraving very durable, damage-resistant and precise.

Laser engraving - types

Depending on the power of the machine and the type of materials that can be marked using them, there are two types of laser - YAG engraver and CO2 engraver. The way in which the laser works is determined by several parameters, including: power, speed and resolution. Laser power is synonymous with the strength of the light beam that is emitted by the device. The higher its value, the deeper the engraving you get. Laser speed refers to the rate at which the beam travels along the material. The resolution, on the other hand, determines the quality of the engraved design.

See: pens with engraving

YAG engraving

The YAG laser is sometimes referred to as a "hard" laser, due to its greater power, and can therefore be used to mark any hard materials - metals and very hard plastics. The effect that can be achieved with this type of engraver varies depending on the type of metal used.

Characteristics and applications of YAG laser engraving

Due to the higher power of the device, YAG laser engraving is slightly deeper and can reach up to 1 or 2 mm. However, this is a risky practice, as to achieve such an effect, a very high amount of heat must be generated, which can lead to damage of the engraved material. Depending on the type and colour of the metal, a different final marking appearance can be achieved with this type of laser. It is also important that the surface has been varnished and is not covered with any additional surface substance. Using a YAG laser, it is also possible to decorate hard plastics, which become discoloured under the influence of the light beam. Again, the end result depends on the type of dye used for the plastic, but this is difficult to predict, as the dye substances used are not always well known.

This type of decoration is most often carried out on jewellery, cutlery, business card holders, photo frames, watches or various devices with plastic cases. Using the YAG engraver, SpiroPrint marks its metal pens with engraving. In addition to this, YAG engraved thermal mugs can also be a great gadget and for the more electronic people we offer pendrives with engraving, which you will also find in our shop.

CO2 engraving

The CO2 laser, known as a 'soft' laser, is designed for marking materials such as leather, plywood, wood, glass, plexiglass and other soft substrates. It can also be used for most organic materials, but is not suitable for metal engraving.

Characteristics and applications of CO2 laser engraving

CO2 laser engraving devices are characterised by lower power and shallower decoration. Generally, it ranges from a few hundredths to about half a millimetre. In some materials, on the other hand, no indentation is obtained at all and the drawing is only caused by a contrasting discolouration of the material under the influence of the laser beam. As with the YAG engraver, the final effect depends on the type of material being processed. The designs produced with it are characterised by very high precision and repeatability, making it possible to produce multiple products with the same design.

The most common applications for CO2 laser decoration are aluminium plaques, key rings, wood and cardboard models, decorated glasses, boxes or book calendars with engraving and planners. In the case of SpiroPrint, CO2 engraving is also used to mark company notebooks.