MANUFACTURER OF ADVERTISING GADGETS | FAST DELIVERY TIME | FREE CONSULTING

Printing House

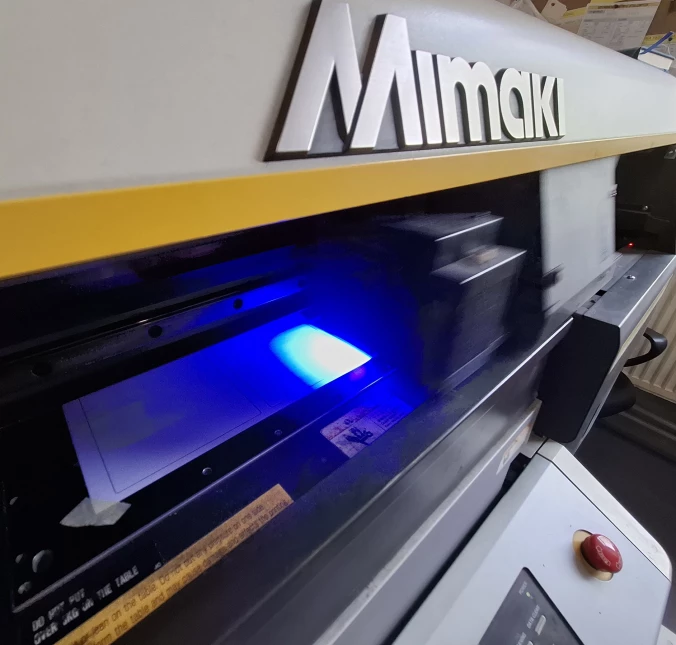

UV printing - what is it?

UV printing is a technique based on the application of special inks to virtually any flat substrate. The ink applied to the substrate dries through the use of UV light. There are two groups of equipment used for this printing method. One is roll-to-roll equipment for quick printing of conventional substrates (billboard paper, mesh banners). The second group are multi-purpose machines with multiple functions, suitable for printing on substrates such as glass, cardboard, aluminium, Plexiglas, PVC, mirror, foil, including roll-to-roll materials.

See: advertising pens

UV printing is similar to that carried out with inkjet printers, but differs in the use of a different type of ink and the use of UV light for its drying. This method is great for large-format surfaces, which is why it is often chosen for printing advertising surfaces. For printing advertisements on fabric,dtg printing is a frequently used method.

Dtg printing is printing directly onto the fabric, and is most often applied to the surface of clothing items such as T-shirts. UV printing is a very common technique, just as popular as DTG printing. UV printing looks spectacular on all materials to which it can be applied, in addition to demonstrating great durability and longevity. The entire UV curing technique has been used in the printing industry for about 30 years. It is a versatile method that allows a full range of colours to be printed. The narrow UV jet guarantees high curing efficiency, thus ensuring a stable and safe print. It allows you to print on a large number of materials, which means increased productivity and lower operating costs.

See: printed lanyards

Advantages and disadvantages of UV printing

Like any other marking method, UV printing also has advantages and disadvantages. Admittedly, the ability to print in full colour is extremely important. Even more so if the ink is cured and more resistant to fading, scratching or smearing. But it is also more expensive, more on that in a moment.

Advantages of UV printing

- No release of noxious odours from already printed surfaces, which could adversely affect the human body. Prints are suitable for use in commercial interiors (flats, restaurants, offices, shopping centres, hotels).

- UV-cured ink is more resistant to fading, smudging and scratching.

- High print durability and resistance to adverse weather conditions. For this reason, it can also be used outdoors (advertisements on buildings, information boards, signs).

- The UV printing method is also suitable for large format printing, as well as for small items, including those with an original shape.

- UV printing produces vivid, intense colours that faithfully reproduce the graphic. The print is vivid, as there is no absorption into the substrate or spreading over the surface. Thanks to the exposure, the ink dries in an extremely short time.

- With the help of multiple printing, relief printing for the blind can be achieved.

- The process of this type of printing is environmentally friendly. UV-curing inks are not based on solvents, so there are no harmful substances that would have to evaporate and thus enter the environment.

Disadvantages of full-colour printing

- The print is not suitable for use on relief objects.

- When using this technique, the odour of the inks being fixed is not very pleasant.

- It is very expensive to print.

- Size of machines used.

Full-colour UV printing - application and operation

UV printing is used in many industries, equally in interior design, event companies, clothing manufacturers, cosmetics companies and many others. The technology works well for corporate identity, decorating hotels and restaurants or large shopping centres. The main customer for printers offering UV printing is, of course, the advertising industry. The technique is also used for signage and navigation systems for large areas. It can be used according to individual customer requirements. The technology finds its way into the marking of bottles and cylindrical glass objects. In our case, pens with company logos, for example, are marked using UV printing. Due to the small size of the light sources, they are great for machines with limited available space. UV printing makes it possible to print on heat-sensitive materials and those with a small thickness.

See: pens with engraving

Printing can be done on curved surfaces, so no additional labelling of bottles is necessary. The technology is also suitable for metal surfaces, even when the metal is die-cut or curved. Necessary corrections and changes can be made during the process without any problems, all thanks to the temperature of the UV light. UV colour printing can also be used on plastic surfaces if the dimensions of the object are not too large. We use it, for example, for memory sticks with logos. The process is suitable for advertising badges or pens, for example.

The ink used for UV printing is a liquid polymer, and together with the print it is exposed to UV light emitted by LED lamps. This starts the polymerisation process of the ink. The print is thus hardened and transformed from its liquid form into a thin, weather-resistant plastic layer.